Combining Science and Design to Create Better Products

Science and design are often placed on opposite ends of the spectrum to each other. Even something with more obviously practical applications like industrial design, is often associated more with furniture and kitchen appliances than developing scientific technology. However, the combination of these two disciplines has an extraordinary amount of potential. To explore this topic in more depth we will be taking ‘PhysioFriend’, a wearable device for physiotherapy rehabilitation, as a case study.

Research suggests that successful recovery from an operation is dependent upon: 50% surgical success and 50% good patient rehabilitation. But often the second part is the hardest. This is something we discovered a lot about from our discussions with surgeons when designing surgical instruments. Patients struggle with their rehabilitation for various reasons, such as forgetting to do the exercises, worrying that they’re uncomfortable, struggling to get the correct Range of Motion for them, and even being held back by their fear of accidentally doing more damage.

Lamb Industries was honoured to be invited as industrial designers to work with material scientists, other designers and engineers on the EU FP7 project: Light Touch Matters (LTM). A unique cooperation with 17 partners from 9 EU countries, with the aim of finding applications for new material in the healthcare industry. The unique properties of this material, which we will go into more detail on later, offered LTM the chance to create a product that could make a huge difference in patient rehabilitation.

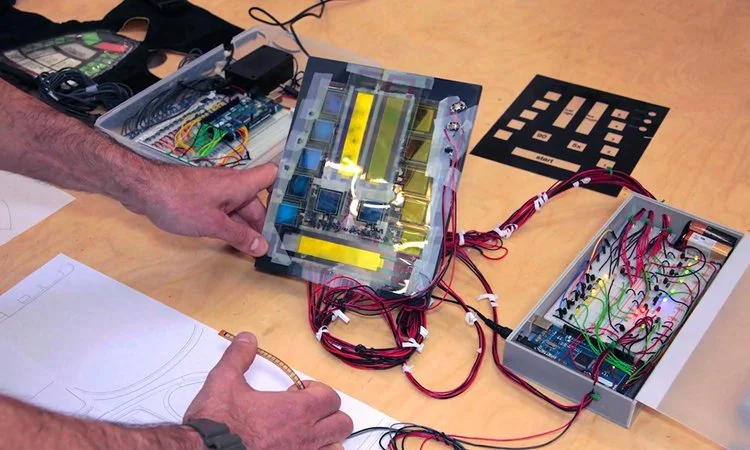

It was truly a fascinating creation process. As designers, Lamb Industries were involved with creating applications for the technology while the technology was being created. This positive feedback drove the direction the technologists took in order to give a more meaningful and useful real-world outcome. It has some interesting potential applications, especially for the medical field, for how design can shape the initial creation process of a product to make it better equipped to serve users.

LTM worked with the latest developments in polymeric piezo materials and flexible OLEDs to combine touch sensitivity with luminosity. Through product-user interaction research, we were also able to explore the meanings elicited by the new materials under development, to encourage users to want to do their rehabilitation exercises and make the process of doing them more enjoyable.

This all resulted in the creation of ‘PhysioFriend’.

This prototype greatly expands design freedom and unlocks totally new modes of product-user interaction, enabling us to take the next step in product design: the product will become the user interface.

This prototype is aimed at knee recovery but there is no reason why the technology could not be applied to other joints. Additionally, beyond rehabilitation exercises, it could even be used by athletes as a training aid to view and record development. Lamb Industries have a technology demonstrator of this product and would be keen to talk with any companies interested in developing it further.

For a further glimpse into the collaborative process that made this possible, you can watch the video below. (Credit to Light Touch Matters for the video). Or see our page on PhysioFriend.